CONCRETE POLISHING IHC CONSTRUCTION GROUP

- Home

- Concrete Polishing

Serving commercial, industrial and residential

We will get you the desired degree of shine and smoothness

Large warehouses and warehouse outlets

Retail stores

Hotels and restaurants

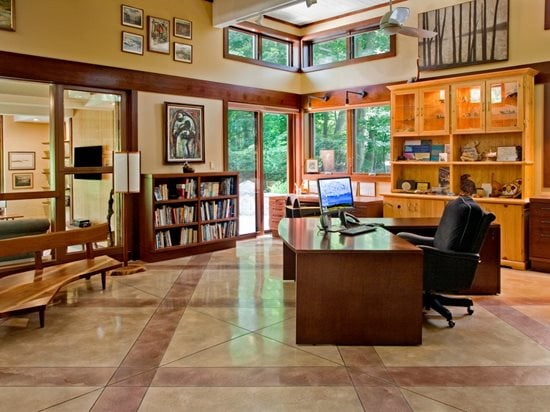

Office buildings

Auto showrooms

Private residences

BENEFITS OF POLISHED CONCRETE

Homeowners, retailers, educational and medical facilities are choosing polished concrete for their floor finish because of the competitive advantage polished flooring offers over other types of floor coverings.Decorative concrete in the form of polished floors has become the logical choice because of the great value it delivers, and because it can compete aesthetically as well.

Concrete Polishing is the process of grinding, densifying, and honing concrete to a smooth surface. The grinding process starts with a low grit diamond, then progressively increasing the grit to a smooth 800 – 3,000 grit level.

ECO FRIENDLY STRONG LOW MAINTENANCE

The concrete is also treated with a chemical densifier. The densifier hardens and seals the concrete from within, eliminating the need for a topical coating or sealer. Concrete floor surfaces, whether new or old, can now be grinded to a high-gloss finish that never needs waxes or coatings. The high-grit polished finish is ideal for high traffic areas and has many benefits over other flooring options.

The benefits of polished concrete floors include:

Decrease in floor maintenance and cleaning costs

Increased strength and durability

Increase ambient light reflection

Elimination of tire marks

Easy to maintain

No waxing and stripping

Non-slip surface

Decrease tire wear and tear

Elimination of dusting

Beautiful and aesthetic

Lowest flooring life cycle cost

Long-lasting

We love the look of a polished concrete floor in a home, office or garage. Call us today for your free LOS ANGELES concrete polishing estimate.

Eco-friendly Aesthetic Durable

ACID STAINS VS. WATER-BASED STAINS

ACID STAINS VS. WATER-BASED STAINS

Stained Concrete Floors-Ideas for Concrete Stains

Stains for concrete come in two general categories: acid-based chemical stains and water-based acrylics. Both types of stain can be applied to new or old and plain or integrally colored concrete. They are especially effective for revitalizing dull, lackluster surfaces. Because they penetrate the concrete surface, most stains have excellent UV stability and wear resistance, permitting their use on interior or exterior concrete.

Applications range from:

- Walkways and patios

- Family room floors

- Kitchen countertops

- Vertical surfaces like walls or fireplaces

Most acid stains are a mixture of water, hydrochloric acid and acid-soluble metallic salts. They work by penetrating the surface and reacting chemically with the hydrated lime (calcium hydroxide) in the concrete. The acid in the stain lightly etches the surface, allowing the metallic salts to penetrate more easily. Once the stain reacts, it becomes a permanent part of the concrete and won’t fade, chip off or peel away. The palette for acid-etch staining is generally limited to earthy tones, such as tans, browns, terra cottas and soft blue-greens.

If you want to go beyond the subtle drama and subdued earth-toned palette of acid staining, consider using water-based stains, which come in a much broader spectrum of hues. Most manufacturers offer dozens of standard colors, including black and white and even metallic tints. Like acid stains, water-based stains (typically a blend of acrylic polymers and pigments) penetrate the concrete to produce permanent color, ranging from translucent to opaque depending on the product.

Like stains for wood, concrete stains are semi-transparent and are intended to enhance rather than disguise the surface. They will not hide cracks, blemishes or other flaws in existing concrete. Nor will they completely mask an underlying color or conceal the texture of the surface. An existing concrete slab with major cracks or spalling is usually not a good candidate for staining because any patchwork is likely to show right through the stain.

Because stains must be able to soak into the concrete to achieve full color saturation, they shouldn’t be applied to surfaces covered by anything that can inhibit stain penetration, such as dirt, grease, glues, coatings, curing membranes and sealers.

INDOOR VS. OUTDOOR STAINED CONCRETE

Most concrete stains on the market today, whether they are water-based or chemically reactive (acid-based), can be used on both interior and exterior concrete. So how do you determine the best product to use for a particular project? The factors that come into play aren’t much different than those you would consider for indoor vs. outdoor painting: exposure conditions, the look you’re trying to achieve, ease of application, and safety and environmental concerns.

Check out these popular staining applications:

- Stained Concrete Patios

- Stained Concrete Floors

- Stained Concrete Driveways

A bowling alley floor colored with water-based stains. Decorative Concrete.

Indoor staining

Is the stain safe for indoor use?

Read the safety precautions provided by the stain manufacturer. For indoor projects where ventilation is poor, concrete stains with a low VOC content will be your best choice. Some chemical stains contain solvents and corrosive components that can cause eye, skin, and lung irritation.

What are the cleanup requirements?

Chemical stains can be messy to use indoors because you must scrub the slab thoroughly after applying to remove any stain residue, followed by rinsing with clean water. Then you must collect all the residue with a wet vac and dispose of it safely (see Acid Staining Basics). Water-based stains are easier and safer to apply indoors because they are free of solvents and acids, and they don’t require neutralization or rinsing.

What look are you trying to achieve?

If you want to match an existing color scheme or make a bold design statement, water-based stains will give you an endless array of color options and, like wall paint, can be mixed to create custom shades. (See how water-based stains were used to add vibrant color to this bowling alley floor.) If you want to achieve rich earth tones with natural marble-like color variations, chemical stains are often the best choice, as long as the proper precautions are taken during indoor application. On this residential floor project, chemical stains in dark walnut and antique amber were used to create an appealing vine pattern.

Is your floor slab emitting moisture?

For the best results, concrete stains should be applied to interior slabs that have a low moisture-vapor emission rate. Some manufacturers recommend performing a moisture-vapor emission test to check for suitability.

Outdoor staining

Is the stain UV- and abrasion-resistant?

Most water-based and acid stains for exterior concrete are UV- and abrasion-resistant. However, because acid stains deeply penetrate and chemically react with the concrete, they may provide greater resistance to fading and wear over time. Both types of stain are permeable to water vapor and act as good barriers to moisture penetration.

An acid stained patio with a scored diamond pattern.

Will acid stain kill vegetation and grass when used outdoors?

For outdoor projects, the fumes from acid stains will not pose much of a problem. However, the residue and runoff from rinsing off the stain must be contained because it could harm the grass and surrounding vegetation. Water-based stains don’t require rinsing and any residue can be safely cleaned with soap and water.

Does the color work with your landscape and home exterior?

If you want to replicate the appearance of natural aged stone, chemical stains will react chemically with the mineral content of the concrete to create a beautiful mottled appearance (see this acid-stained patio). Water-based stains are non-reactive, so the color tends to be more opaque and uniform. However, water-based stains will give you more color options and the ability to customize colors to coordinate with the color scheme of your home exterior. For this residential driveway project, solid-color water-based stains were used to match the home’s existing design scheme.

Use a good sealer

Whether you’re staining indoor or outdoor concrete, all stained surfaces should be protected with an appropriate sealer, which is determined by the type of stain, exposure conditions, and the level of traffic. Not only does the sealer provide protection from day-to-day wear, it also enhances the color and determines the gloss level of the finish. For indoor projects, lower gloss levels tend to be easier to clean and won’t show wear or surface scratching as much as high-gloss sealers. Learn more about choosing the best sealer for your project.

Call us today for your free estimate:

CONCRETE FLOOR PROS, CONS & DESIGN IDEAS

Get ideas and learn about all the benefits of concrete flooring, from unlimited design versatility to easy maintenance Polished Concrete

Polished Concrete

Concrete floors are a great alternative to linoleum, carpet, wood, tile, stone or marble flooring. Concrete can be stained nearly any color, resurfaced in a variety of textures and finishes, or polished for a smooth, shiny look. Plus, concrete flooring is durable, long-lasting and easy to clean and maintain.

If your home or business has concrete subfloors, exposing them and applying a decorative treatment is an affordable and environmentally friendly option. Learn more below.

PROS & CONS OF CONCRETE FLOORS

Concrete flooring has many benefits, compare them to the drawbacks below to determine if concrete is the right option for you.

Advantages:

- Can be designed for any budget

- Unlimited creative options

- Requires little maintenance

- Will last for decades (50+ years)

- Resists moisture and stains when properly sealed

- Pet friendly

- Reduces allergens in the home

- Can be heated with a radiant system

- Free of VOCs (volatile organic compounds)

Concrete Arts

Disadvantages:

- Requires occasional resealing

- Can be difficult to patch

- You may need area rugs for comfort and warmth

- Cracks can develop over time

- Can become slippery when wet

WHERE ARE CONCRETE FLOORS USED?

Kitchen:

No other room gets as much use as the kitchen, so it needs to have the most durable flooring surface possible. Concrete can withstand the foot traffic and elements that kitchen floor surfaces are exposed to, while also bringing endless design options to the table. Plus, there aren’t any joints or grout lines to trap dirt or spills, so clean-up is a breeze. See more about kitchen flooring.

Entry, Foyer, Mudroom:

Make a great first impression with a stylish entry, foyer or mudroom decorative floor. Concrete’s easy care, ability to handle heavy foot traffic and resist staining make it the perfect choice for busy areas where dirt, mud and water might get tracked in. Read more about how to create a grand entrance.

Stained Concrete Floors

Bathroom:

When deciding on flooring for a bathroom, you want something that is stylish, durable, resistant to moisture and spills, as well as low maintenance. Concrete checks all of those boxes. Radiant heating can also be installed to keep the floor comfortable for bare feet. Learn more about bathroom flooring options.

Basement:

Concrete is an exceptionally good choice for basement flooring due to its moisture resistance in these areas that are typically subject to ground moisture and possible flooding. With concrete, you can avoid mold and mildew problems and having to pull up and replace damp carpet or damaged wood flooring. Add a fun feature of hopscotch or shuffleboard into the design. Check out more ideas for basement floors.

Garage:

With many garages being used as extensions of living space, why not make them as attractive as the rest of the home. Looks can range from sealed or polished basic gray to more complex color combinations. Add colored flecks for a terrazzo look or a custom design with brightly colored epoxy coatings. See more garage flooring options.

Commercial:

Concrete combines durability for heavy use, high-traffic areas with endless customization options. These two factors combine to make it a perfect choice for retail stores, restaurants and bars, offices, churches, schools, medical institutions, and industrial buildings, making it possible to incorporate your company logo, colors or theme right into the floor. See more on commercial applications.

Polished Concrete Floors

COST OF CONCRETE FLOORING

One of the major benefits of decorative concrete flooring is its affordability when compared to other options, particularly if you already have a concrete slab that’s ready for staining, polishing or application of a coating or overlay. The cost per square foot for a basic design is comparable to linoleum, vinyl, carpet or lower-priced ceramic tile. Mid-range designs are comparable to laminate, bamboo, hardwood and more expensive tile. Higher-end designs are about the same as slate, stone, or marble.

Basic Concrete |

Mid-Range Concrete |

High-End Concrete |

The above pricing is based on basic installation in a square area. Factors such as cabinets, cut-outs, angles and stairs can contribute greatly to cost variances.

Decorative concrete flooring can increase the resale value of a home, because new owners can install their preferred flooring right over the top without incurring removal and disposal costs, or choose to keep the concrete as is. The long-term value should also be considered, as concrete will provide decades of use with very low maintenance, saving you money over the lifetime of the floor.

Other elements that may affect cost include:

- Moldings or baseboards that need to be worked around or removed

- The need for special underlayments

- Removal and disposal of existing flooring

- Subfloor repair

- Moving furniture

Confirm with your contractor exactly what is, and isn’t, included.

DESIGN OPTIONS

Colors:

The most popular color choices tend to be neutral grays and earth tones; however, the possibilities are nearly limitless. Color can be mixed into the concrete (integral color) or applied to the surface with stains, dyes, epoxy coatings, tinted sealers or with a combination of one or more of those methods. Concrete can be colored so naturally that it blends seamlessly with other elements in a room.

Stained Floors:

Stained concrete is incredibly popular because of the warm, earthy tones the stains impart. Looks can be achieved to replicate marble, wood, brick, stone and more. Acid-based stains are available in earth-toned palettes and water-based formulas offer a broader range of color options.

Polished Floors:

Create the ultimate no-wax floor with polished concrete. Various levels of sheen from satin to high-gloss can be achieved through this multi-step process. Create an industrial look with polished natural gray concrete, or combine the numerous coloring options for an endless list of possibilities.

Designs and Textures:

In addition to colors and finishes, there are countless design possibilities that can be applied to your floors. Stamps and texture skins can be used to produce finishes that resemble wood, stone, brick, and more. You can create a look that resembles tile or score a design right into the surface with saw cutting. Logos and graphics can be incorporated with stenciling or engraving. If your existing surface has minor flaws or cracks, these can often be camouflaged or worked right into the design by skilled contractors, or simply used to add character.

Radiant Heating:

This dust-free heating method can be installed in newly poured concrete or with an overlay. Radiant heat is especially beneficial to those suffering from respiratory issues and allergies because air isn’t forcefully blown throughout the house and outside air isn’t brought in. You’ll also enjoy the added benefit of saving money on heating costs.

ACI Flooring in Beaumont, CA

Overlays and Microtoppings:

If your concrete has minor imperfections, stains, or cracks, an overlay or microtopping might be the answer. Properly installed overlays are just as durable and long-lasting as standard concrete. Stampable overlays allow you to apply stamped or textured finishes, colors, and stains just as you would to newly poured concrete. There are even overlay products that allow you to cover vinyl, tile or wood surfaces. Read more about making the switch to concrete.

Learn more about interior floor finish options and design ideas. Call us today for your free consultation: (323) 329-7068

PROTECTION, MAINTENANCE & REPAIR

The maintenance needs of concrete flooring depends upon the amount and type of traffic it receives, but with minimal upkeep, your concrete will provide you with decades of use. Your contractor can recommend a maintenance schedule that fits your surface and location.

Sealers:

When decorative floors are installed, they should be sealed properly. A good interior floor sealer will prolong the life of the concrete, provide protection from scuffs and stains, prevent moisture problems, as well as enrich the color and enhance the shine of the floor. Your contractor can recommend the best sealer for your particular application.

Wax:

If the floor receives heavy foot traffic, such as in a restaurant or retail store, a concrete floor wax can be applied occasionally as a sacrificial layer to preserve the sealer and protect the integrity of the floor. This top layer absorbs daily wear and tear and is easier to buff out and reapply than sealer.

Cleaning Stained Floors:

For properly sealed residential floors, a basic cleaning routine of sweeping and damp mopping is enough to keep the floor in top condition for years. For an occasional deeper cleaning, use water and a pH-neutral cleaner. Door mats and area rugs also help protect high-traffic or spill-prone areas. Read more about caring for decorative concrete flooring.

Cleaning Polished Floors:

Daily dust mopping will keep particles off the floor and protect the surface from abrasion. Because of the densification that occurs in the polishing process, polished surfaces don’t require sealers or waxes. They can get dull with years of high-traffic use, but buffing the surface can restore the original shine. Learn more about maintaining polished floors.

Repair:

Unfortunately, one of the drawbacks of decorative concrete flooring is the inability to easily repair or patch it. The texture and finish of the concrete, as well as the color and tone of the stain all need to be matched. This can be quite difficult, as each batch of concrete will cure and take stain differently. However, there are options such as working the patched area into the current pattern or creating a new design with a stencil or engraving. An overlay or microtopping can be applied, or as a final option, use a throw rug or furniture to hide the area. Consult an experienced floor contractor for advice.